Increasing Proppant: Not Always The Best Solution

Thursday December 3, 2015

Seems like it happens all the time, doesn’t it? You’ve been craving your favorite dish at your go-to restaurant all week. You finally get there on Friday night only to find out they don’t serve it anymore. What do you do? You’ve already been waiting for a table for almost an hour, you’ve already pierced the wall of people around the bar and gotten the first round of refreshments, and your group even managed to find free parking. Then, somebody says the words, “We might as well just stay here and try to make the most of it.”

You order a different plate, but is it as good? Of course not. And sprinkling extra hot sauce or parmesan cheese on top of it doesn’t make it much better. Still, it is instinctual to try to make the best out of any given situation, even after finding out the results will never measure up to something more ideal.

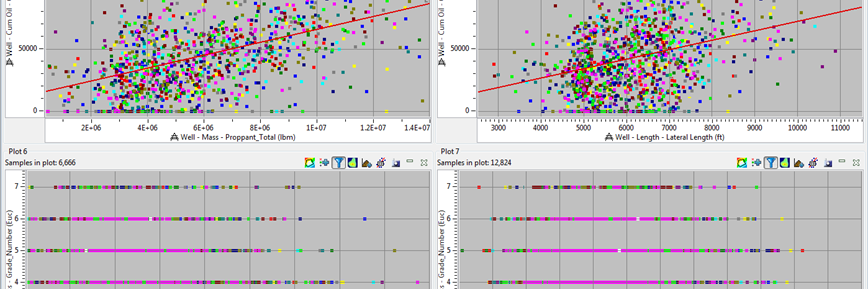

Oil firms are no exception.While working with Senior Geologists & Senior Engineers at a small but successful onshore operator a few weeks back, one of the more surprising statistics that an Analytics workflow yielded was the fact that total proppant usage was actually inversely related to 12 month CUM production. Now, it should be said that the focus area involved fewer than 100 wells and that the relationship was minimal. Even still, pumping more proppant yielded smaller predicted production CUMs.

Much to the frustration of the whole group involved, we reconvened with a logical conclusion. They revealed that when they drill the pilot wells and analyze the log data, sometimes they learn that they’re in bad rock. The interval is thin, the porosity/permeability is low, the reservoir is heavily faulted and structurally complex, etc. Geology matters! So, after they learn this, the two engineering parameters they make changes to are lateral length and total proppant. They drill farther out, and they push more sand. Ultimately, what you have are very expensive, very long, heavily-propped wells that have low CUMs. Did production get better after their enhanced completions strategy? Probably. But did it yield a healthy ROI? Likely not.

And this is hoping that the Geosteering process goes well. For 250ft thick Bone Spring sand intervals, this may be no problem. But thinner plays like the Marcellus are a different story. And unless you’ve got the most up-to-date logging technology, you may be logging 90+ feet behind the drill bit. And correcting a...